Insulation piercing connectors are indispensable components in AB cable systems, serving both messenger wire and self-supporting systems that require tap connections. These connectors play a crucial role in the distribution of power lines, facilitating street lighting and domestic utility connections. With their innovative design, they boast a remarkable ability to completely seal the connection against water penetration, making them highly reliable and waterproof.

The key feature of these connectors lies in their ability to establish a semi-permanent metal-to-metal connection between the wire conductor and the insulation piercing connector. This ensures a strong and durable bond that can withstand various environmental factors. The performance and dependability of these connectors are influenced by several important factors, including the contact type, connection method, and tip design. These factors are carefully engineered to optimize the efficiency and longevity of the connectors, guaranteeing a secure and stable connection for extended periods.

To explore the wide range of insulation piercing connectors we offer, I invite you to visit our website. There, you will find an extensive selection of connectors designed to cater to diverse needs and requirements. Should you require a quotation or have any further inquiries about our connectors, please don't hesitate to contact us. Our team of experts is available to assist you and provide the information you need to make an informed decision.

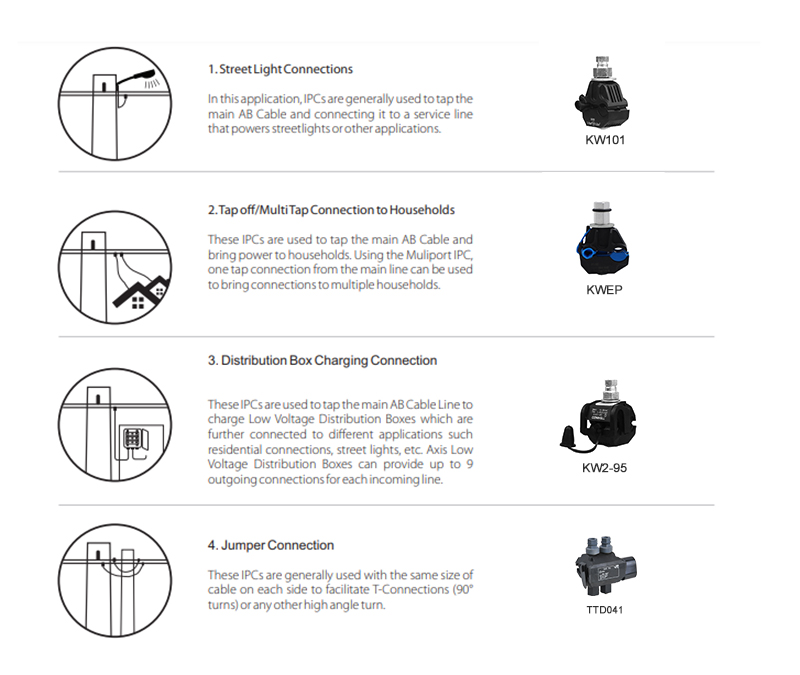

Various types of IPC using standard EN 50483-4:2009:

Advantages of Insulation Piercing Connectors

Insulation piercing connectors offer numerous advantages and features that make them a reliable choice for various applications:

-- Secure Fastening: These connectors are designed to be securely fastened with the pole structure, ensuring a stable and strong connection. This helps to prevent any unwanted movement or disconnection.

-- Dependable Connection: Insulation piercing connectors provide a dependable connection, ensuring a consistent flow of electricity without interruptions or voltage drops. This reliability is crucial for street lighting and domestic utility connections.

-- Robust Construction: With their robust construction, these connectors are built to withstand harsh environmental conditions and mechanical stress. They are designed to be durable and resistant to corrosion, ensuring a long lifespan.

-- Durable and Long-lasting: Thanks to their durable construction and materials, insulation piercing connectors are built to last. They can withstand various weather conditions and continue to perform reliably over an extended period.

-- No Conductor Insulation Stripping: One of the notable advantages of these connectors is that they eliminate the need for stripping the conductor insulation. This saves time and effort during installation while maintaining the integrity of the insulation.

-- Wide Voltage Range: Insulation piercing connectors are suitable for non-tension lines with voltage levels of up to 600 Volts, depending on their size. This versatility allows them to be used in a wide range of applications.

-- No Post-Installation Tape Required: Unlike some other connectors, insulation piercing connectors do not require additional tape or sealing materials after installation. Their design ensures a watertight connection, eliminating the need for additional protective measures.

-- Versatile Applications: These connectors are useful for various applications, including copper-to-copper, copper-to-aluminium, and aluminium-to-aluminium connections. This versatility allows for flexibility in different electrical systems and setups.

Post time: Apr-14-2023